Ultra High Molecular weight Polyethylene, which is popularly referred to as UHMWPE, has become a household name in the industrial sectors that require durability, low friction and chemical resistance. Among others, uhmwpe plastic sheet and plates, which are all characterized by superior performance in high-impact and abrasive operations. Though the terms plates and sheets are used interchangeably, in most cases, there are some slight variations, which define how the terms are used, handled, and the nature of the projects that they can be applied to. The engineers, manufacturers and designers are interested in these differences since they are willing to exploit the potential of this multi-purpose material.

Defining UHMWPE Sheets

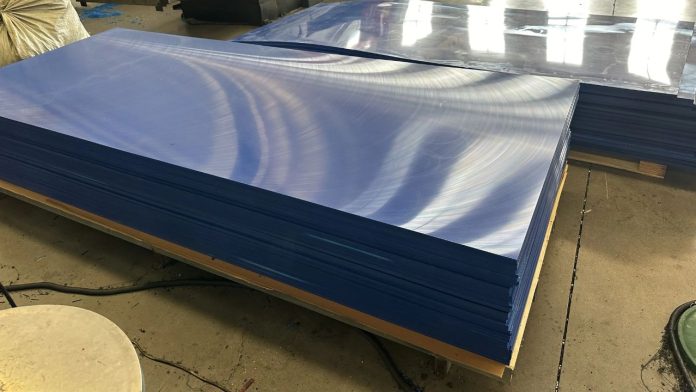

UHMWPE sheets are commonly produced to constant depths and are frequently sold in common sizes that are easy to cut, shape and manufacture. They are also easy to install due to their constant thickness and smooth nature, which is used in works that require sliding surfaces or wear resistance. UHMWPE sheets are very light but extremely powerful and provide impact resistance and low friction characteristics, which makes them a perfect choice of liners in chutes, hoppers and conveyor systems. They are especially appreciated in those industries where the flow of materials and wear of the equipment is extremely important.

Sheets are widely applied in food processing, packaging, and industrial operations where hygiene, chemical inertness, and easy cleaning are considered. The reason is their non-porous material, which means that moisture cannot get into the material, and the material is stable even under humid or wet environments. Also, UHMWPE sheets may be cut using standard woodworking or plastic processing tools and cut into shape to match a specific requirement.

Understanding UHMWPE Plates

The plates are usually more robust and thicker compared to sheets and are made of the same material, UHMWPE. Plates are made to be utilized in heavy-duty jobs which demand extra strength, rigidity and resistance to impact. They are commonly applied in a scenario where load-bearing or structural support is the most important factor. Since the plates are thicker, they are able to endure more mechanical stress without deforming. Thus, they can be used in construction, industrial machinery and in environments that may have abrasion, thereby withstanding high stress levels.

The plates are normally selected when extreme conditions of longevity are required. They are better at protecting surfaces that are subject to constant shear and high-impact loads. Plates are sometimes harder to cut and shape because of their thickness. They are generally tough enough to warrant the additional effort. Moreover, they are very resistant to chemicals and moisture and therefore can be used in violent or corrosive environments.

Key Differences between Plates and Sheets

The major difference between UHMWPE plates and sheets is the thickness and structural rigidity. Sheets are more lightweight, easy to manipulate, and thinner, which makes them applicable in the context of flexibility and accurate shape. On the contrary, plates are heavier and stronger and can support heavier loads and wear out more rapidly. Although they have the same low-friction, high-durability, and chemical-resistance properties, their application in certain environments would depend on the requirements of the work environment and the type of workpiece.

The other distinction is the fabrication and installation. It is easy to cut, drill, or mill sheets; hence, adapting to existing equipment or designing something was fast. Plates are also machinable, but can be heavy and/or hard to handle because of their thickness. This is why sheets are popular in projects when a good amount of adjustments or modular parts are required. In contrast, plates are more applicable to the projects where long-term installations are in focus, and the durability and structural integrity are the most important factors.

Choosing the Right Option

When choosing between UHMWPE plates and sheets, there is a consideration of the needs of the application. The load, impact, wear resistance, and installation feasibility are the factors that should be considered by engineers. Sheets can also be the best tradeoff between performance and convenience in lightweight, flexible applications that have moderate wear. In the case of heavy-duty conditions, when the material will be subjected to huge stress and abrasion, plates are often used.

Conclusion

However, finally, both UHMWPE sheets and plates have the distinguishing characteristics of this high-performance polymer, that is, a high level of stability, low friction, resistance to chemicals and moisture, and prolonged performance. This knowledge of the slight variation between these two forms can enable practitioners to make the right decisions, and the material has to be able to address the functional requirements as well as the operational ones.