What is the Value of Heavy-Duty Gauge Hinges on Long-Term Performance

Garage doors are dependent on a system of parts that collaborate to create a level of movement that is smooth and reliable. Hinges are the key elements among them, which are used in attaching door panels and facilitate the movement of a roller, making the door move safely and efficiently. Although conventional hinges might be sufficient in certain cases, garage door hinges heavy duty offer a strong momentum of power, dependability, and durability over time. Their construction and load-bearing ability make them a very important factor in the performance of a sectional garage door, particularly one that has intensive or rigorous usage.

The Concepts Behind Heavy-Duty Gauge Hinges

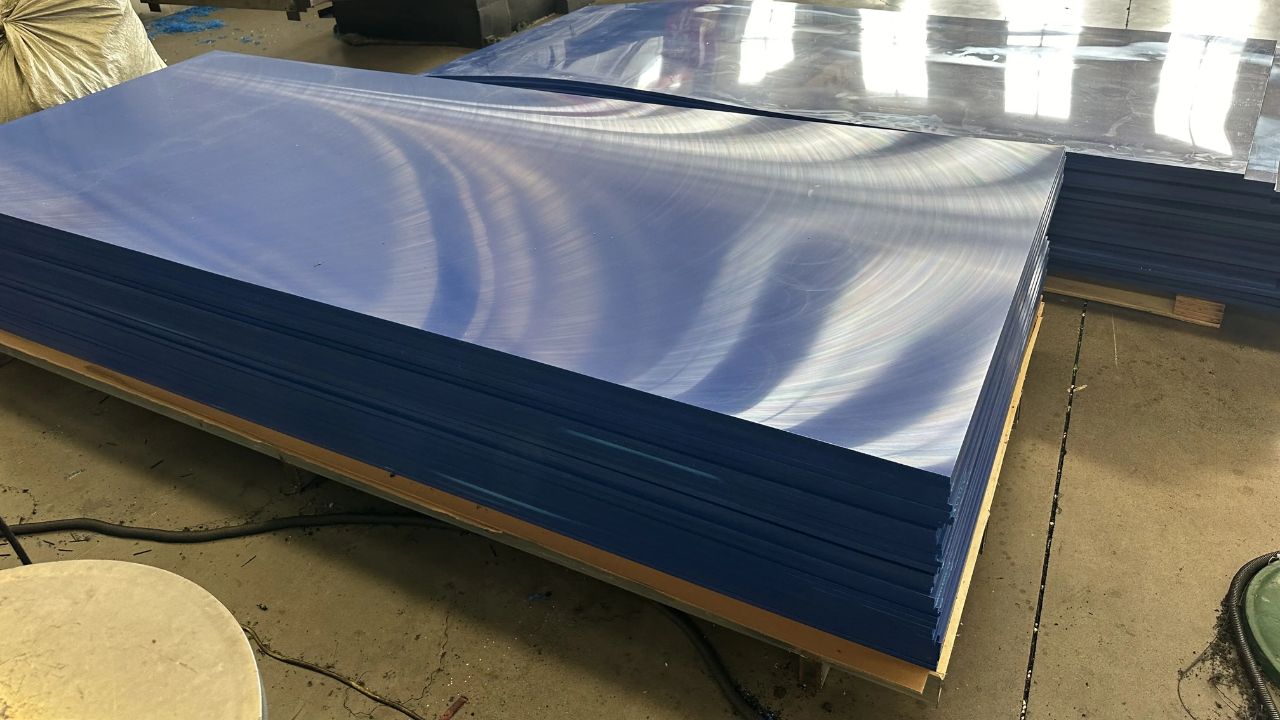

The heavy-duty gauge hinges are made of more robust and more sturdy steel than the normal hinges. Gauge is the thickness of the metal, and the lower the gauge number, the heavier the hinge is, hence more durable. As an illustration, the 14-gauge or 11-gauge steel hinges are known to be highly strong and withstand stress. These hinges are made to suit the garage door that needs more structural support, such as heavy residential doors, insulated panel doors, and commercial doors.

The construction of their structure has made sure that the hinge is capable of walking through the cycles of opening and closing without bending, warping, or weakening. This renders them in areas that have a high frequency of use of the door, are exposed to the weather conditions, or those that support larger and heavier door parts.

Superior Load-Bearing Capacity

The main reason why heavy-duty hinges are important is that they help to hold considerable weight. Sectional garage doors impose a lot of pressure on the hinges, particularly the lower hinges that are the ones that bear most of the burden. In case the hinges are inferior or are composed of thin metal, they can be subjected to pressure and may end up being deformed, leading to misalignment or even failure.

Heavy-gauge hinges are used to spread the weight, and this decreases the pressure on the individual panels as well as rollers. They provide that the movement of the door is not undue and rough when the door is heavy, insulated, or subjected to everyday high-cycle operation. These hinges are useful in avoiding early wear on other parts, including tracks, rollers, and springs, by offering improved stability to these parts.

Securing Long-Term Door Alignment

Any garage door must be free to be in line to work safely and efficiently. The misalignment can result in noisy working, the nonlinear movement, and the strain of the opener, in addition to the safety risk. Heavy-duty hinges help ensure the alignment of panels attached to the hinge is maintained so they remain in the track.

Their extreme stiffness causes them to keep the panel in the correct position over the years of operation, and the fact that they can bend and distort significantly less than lightweight hinges makes this possible. Hinges with high weight used do not change shape or function even under the irradiation of external forces, e.g., vibration, high cycling, or variation of temperature. This will help in the prevention of the gradual shifting that is normally associated with weaker hardware, and ensure the structural performance of the door will be the same.

Advancing Safety and Operational Reliability

The use of safety is among the most significant concerns in selecting garage door hardware. The hinge may break, thus making the door lock, tip, or even fall over, posing hazardous scenarios to persons in the area. Heavy-duty hinges reduce such risks as they provide high structural integrity.

Their reliable construction has ensured that every panel is stably attached even in extreme circumstances. This makes it less likely to have accidents caused by malfunctions caused by damaged or defective hardware. A stable hinge is also one of the factors that help in the smooth and predictable oscillation of the door, which enhances safety in the daily functionality of the users.

Enhancing Productivity

Garage doors are subjected to various weather conditions, such as humidity, temperature fluctuations, seaside air, and dust, as well as frequent mechanical strains. Heavy-duty hinges are commonly galvanized or zinc-plated, which prevents rust and corrosion. This renders them appropriate in the garages that are situated in the coastal area, in industrial locations, or places that are extremely humid.

They have high resistance to wear by the environment, with the result that they maintain their performance and strength far longer than ordinary hinges. Where the metal wears out easily in harsh climatic conditions, the heavy-duty hinges are highly relevant in order to maintain the integrity of the door.

Conclusion

Sectional garage doors are mostly suitable due to heavy-duty gauge hinges, which guarantee long-term performance, safety, and reliability. They are superior in that their strength, durability, and ability to withstand the stresses of the environment make them the best option both in residential and commercial use. They increase the life of an entire door system by distributing the loads better, increasing the alignment, and minimizing the maintenance needs. The decision to pick heavy-duty is not an enhancement but a clever long-term investment in the functionality and safety of a garage door.