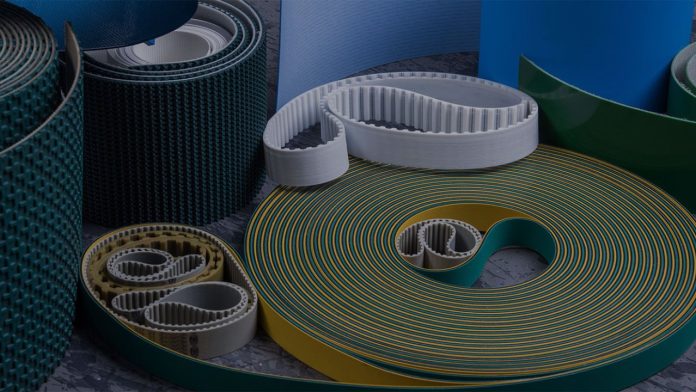

The Timing Belt in modern machinery should not be overlooked, as it provides the necessary accuracy in aligning the movement of various machinery. To achieve operational efficiency, minimize wear and tear, and eliminate unwanted downtime, it is necessary to always choose the appropriate timing belt. Since there are many types of timing belts in the market, which include polyurethane (PU) belts, rubber belts that are reinforced with different materials, it is important to select the appropriate belt after a keen consideration of the needs and working conditions of the machinery.

Learning About Timing Belt Types

The main purpose of timing belts is to pass the power and coordinate the movement of the shafts without slippage. Polyurethane and rubber belts are the most popular varieties of timing belts. Polyurethane belts have been characterized by their stability, chemical resistance, and extremely high temperature withstanding properties. Timing belts made of rubber, usually reinforced with fiberglass or steel cords, are very flexible and offer good shock-absorbing properties. Besides, timing belts can also be classified based on tooth profiles (HTD, STD, and GT series), with each having a particular set of applications and load capacity. The initial process in choosing the most appropriate belt to use in machinery is to know the differences between the various belt materials and tooth profiles.

Load and Torque Requirement Analysis

The load and torque requirements of the machinery are one of the most important factors in selecting a timing belt. Application in the high torque range, e.g., heavy-duty industry machines, conveyor systems, etc., demands a reinforced core in the belt, e.g., steel cords, to ensure that they do not stretch or break. Intermediate torque machines can be used with normal polyurethane or rubber belts. Proper estimation of the load of the torque, considering the peak and the average values, is also accurate, and then the chosen belt can also work under any circumstances.

Consideration Operating Environment

The environment within which the timing belt works also contributes a lot to the selection of the timing belt. Belts may have to be manufactured using more resistant materials with machines that are subjected to extreme temperatures, chemicals, and high humidity. Polyurethane belts are superior in settings that experience the issue of chemical exposure, whereas rubber belts might show more suitability in normal temperatures. Timing belts may be affected by dust, debris, and other contaminants, which wear out the belt faster, and thus it is vital to take into consideration some enclosed designs or other belts with protective coating in such an environment. Assessing the environmental parameters, the operators of the machinery will be able to prolong the life of the belts and guarantee stable work.

Calculating Belt Length and Belt Width

The right size of the belt in length and width is critical to allow the belt to strike the pulleys and transmit power effectively. A belt that is not of the right size may result in slippage, misalignment, and early wear. The manufacture of machinery tends to give specifications of recommended belt dimensions. Non-standard pulley setups or different center distances might, however, need careful measurements for custom applications. Peculiar attention is required to measure the pulley diameters, the center distances, and the number of teeth to identify the right belt length. In a similar sense, the correct selection of the belt width can be used to make sure that the load is evenly spread along the belt so that each of the teeth does not have to carry too much stress.

Measuring Speed and Precision Requirement

Timing belts are also used to transmit power as well as control the synchronization of moving parts. Speedy machines, like printing presses or textile machines, require belts capable of making a smooth running time without extending or slipping. Belts that have high-quality reinforcement materials and have optimized tooth profiles are best suited for applications that require a high level of precision. Furthermore, self-tracking belts or belts with tooth designs can minimize vibration and noise, which will make operations smoother and increase the life cycle of the belt. Knowledge of speed and precision requirements assists in the choice of the belt that would be a performance and life standard.

Conclusion

Proper consideration of several factors, such as belt material, load and torque needs, operating conditions, belt size, speed, accuracy, and maintenance, is one of the factors that must be considered in selecting the appropriate timing belt to fit machinery. A careful analysis of these aspects by the operators would allow maximization of performance, reduction of wear and tear, and increase the life of the belt and the machinery that it drives. The choice of an efficient timing belt that is specific to the needs of the application is not just a choice of taste but a step that is essential in bringing efficiency and reliability in operations within the industrial and commercial environments.